Material testing is a fundamental type of testing performed by engineers and researchers across industries to determine a material’s performance under various stress conditions. Whether developing new products or ensuring quality control, material testing ensures that materials are strong, durable, and reliable in their final applications.

Types of Material Testing

Different types of material tests evaluate specific characteristics of a material. Here are some of the most commonly used methods:

- Compression testing: Determines the behavior of material under load and the ability of it to recover after the compressive force is applied or even held over a period of time.

- Tensile testing: Determines the maximum load that a material can withstand by applying an axial stretching load on the material.

- Peel testing: Measures the adhesive bond strength between materials, commonly used for seals and packaging.

- Bending testing: Determines the load and deflection required to reach the break limit by bending a material until the material experiences a break.

- Friction testing: Determine the ease of the two surfaces sliding against each other., useful for materials that interact in motion.

How can we test a material up to Australian standards?

There are a variety of industry standards which are mostly based on the sample material under test. The following is a listing of some of the most common international testing standards.

| ASTM A370 | Standard Test Methods and Definitions for Mechanical Testing of Steel Products |

| ASTM D638 | Standard Test Method for Tensile Properties of Plastics |

| ASTM D5034 | Standard Test Method for Breaking Strength and Elongation of Textile Fabrics (Grab Test) |

| ASTM D575-91 | Standard Test Methods for Rubber Properties in Compression |

| ASTM D1876 | Standard Test Methods that Adhesive Peel Strength Testing |

Material testing systems, when chosen correctly, can perform specimen testing according to the standard above. Different types of testing machines can be used to test different types of materials to ensure your test results are reliable.

At Bestech, we supply testing machines calibrated and certified according ISO 9001:2015 and also offer technical supports of our products including services, repairs and calibration.

What types of material can be tested?

A wide variety of materials can be tested, including:

- Metals

- Plastics

- Wood

- Rubbers

- Adhesives

- Papers

- Composites

Each material and test type may require different testing grips and fixtures.

Choosing the Right Grips for Your Application

Choosing the right grip is essential to ensure the accuracy of your testing procedure. We offer a wide range of grips and fixtures for different varieties of test types. Selecting the suitable grip depends on the material and test types. Examples include:

- Compression platens are used for general compression testing. It is available in aluminium for soft samples such as cardboard, plastics, rubber and foams, and in hardened steel for the testing of rubber, plastics, heavy duty springs, building products, composites and ceramics.

- Bending jigs are suitable for bending applications on metal, wood, glass, composites and glass.

- Pneumatic grips are suitable for use in a thermal cabinet.

- Wedge grips are used for general tension testing of metals and plastic.

- Rope grips are applicable for filaments, cords, yarn, fine wires, narrow ribbons and ropes.

Real World Applications: Peel Testing

Peel testing is generally used to measure the bond strength of adhesive seals on packages, such as food packets and blister packs. It ensures the seal is strong enough to protect the contents but still easy to open.

When assessing the seal strength of different adhesive bonding, peel testing is essential. While some bonds, for instance, those used in consumer packaging, are meant to break at low effort; others used in automotive applications need to be able to tolerate extreme circumstances. It is crucial to fully comprehend how your bonding will perform in their final applications when producing adhesives. Common results from a peel test are initial peak force, average force over the seal, and peel strength. Keep in mind that temperature variations over time can also impact the strength of adhesive connections, therefore environmental factors and specimen conditioning are also important.

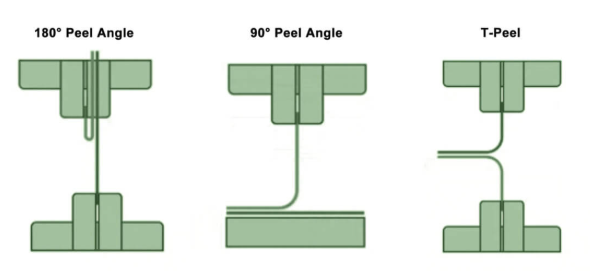

The peel testing system consists of load frame, load cell, tensile grip and peel testing frame. Most peel tests require at least one tensile grip, while the use of specialised testing fixture can help to maintain a preferred peel angle throughout a test. The type of test and the material being tested will determine the type of accessories required, and any material can be tested with a single machine by just changing the fixture.

Common types of peel tests include:

- T-Peel Test

- 90° Peel Test

- 180° Peel Test

Material testing is essential for product development, quality assurance, and compliance with industry standards. Choosing the right testing machine, along with the correct grips and fixtures, ensures precise, repeatable, and reliable test results.

Need help choosing the right material testing equipment?

Contact Bestech to speak with our experts about your testing requirements and we will help to find the best solution for your materials and applications.