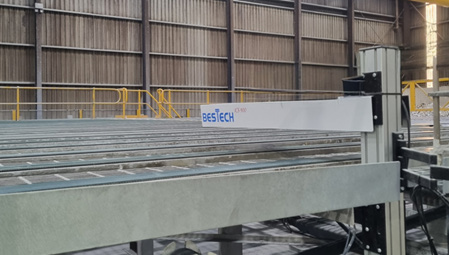

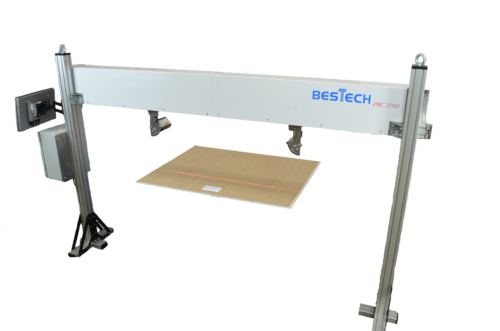

Bestech plasterboard measurement systems is locally manufactured in our factory in Dingley. It is designed for quality monitoring during manufacturing of plasterboard and offers precision measurement of dimensional properties. Our advanced systems, including both offline and online solutions, utilize cutting-edge technology to deliver reliable and accurate measurements, helping manufacturers optimize production processes and achieve consistent product quality.

Key Features of Our Plasterboard Measurement Systems

Our plasterboard measurement systems are engineered to meet the evolving needs of the construction and building materials industry. They include:

- Non-contact dimensional measurement: Leveraging laser-line scanning technology for precise, real-time monitoring.

- Comprehensive quality control: Measure critical parameters such as board thickness, edge angles, recess widths, and recess depths.

- Customizable settings: Easily programmable for multiple board configurations, ensuring flexibility for various production lines.

- Real-time feedback and alarms: Intuitive interfaces provide real-time measurement profiles and color-coded alarms for fault detection.

- Seamless data integration: OPC communication enables streamlined data reporting and recipe management for improved operational efficiency.

Applications

- Plasterboard manufacturing: Ensuring consistent dimensions and quality for building materials.

- Construction material quality assurance: Detecting and rectifying faults to meet industry standards.

- Reducing production waste: Early fault detection minimizes material waste and enhances cost efficiency.

Why Choose Bestech for Plasterboard Measurement Systems?

With over two decades of experience in sensors, instrumentation, and quality control solutions, Bestech Australia is your trusted partner for high-precision plasterboard measurement systems. Our Australian Made certified products reflect our commitment to innovation, reliability, and local manufacturing excellence.

Bestech plasterboard measurement systems is locally manufactured in our factory in Dingley. It is designed for quality monitoring during manufacturing of plasterboard and offers precision measurement of dimensional properties. Our advanced systems, including both offline and online solutions, utilize cutting-edge technology to deliver reliable and accurate measurements, helping manufacturers optimize production processes and achieve consistent product quality.

Key Features of Our Plasterboard Measurement Systems

Our plasterboard measurement systems are engineered to meet the evolving needs of the construction and building materials industry. They include:

- Non-contact dimensional measurement: Leveraging laser-line scanning technology for precise, real-time monitoring.

- Comprehensive quality control: Measure critical parameters such as board thickness, edge angles, recess widths, and recess depths.

- Customizable settings: Easily programmable for multiple board configurations, ensuring flexibility for various production lines.

- Real-time feedback and alarms: Intuitive interfaces provide real-time measurement profiles and color-coded alarms for fault detection.

- Seamless data integration: OPC communication enables streamlined data reporting and recipe management for improved operational efficiency.

Applications

- Plasterboard manufacturing: Ensuring consistent dimensions and quality for building materials.

- Construction material quality assurance: Detecting and rectifying faults to meet industry standards.

- Reducing production waste: Early fault detection minimizes material waste and enhances cost efficiency.

Why Choose Bestech for Plasterboard Measurement Systems?

With over two decades of experience in sensors, instrumentation, and quality control solutions, Bestech Australia is your trusted partner for high-precision plasterboard measurement systems. Our Australian Made certified products reflect our commitment to innovation, reliability, and local manufacturing excellence.