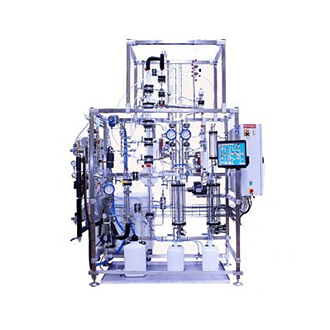

The DIS3000 Batch Distillation Column is an educational unit operation system designed to demonstrate industrial-scale batch distillation for academic and technical training. The column is made with high-quality borosilicate glass to allow students to explore the fundamentals and advanced concepts of vapor-liquid separation using various mixtures such as water/ethanol and ethanol/propanol mixtures.

The system features a 6L glass kettle, a three-section packed distillation column with Multiknit internals, an electromagnetic reflux valve, and a stainless steel coil condenser. Integrated instrumentation includes five temperature probes and a flowmeter, allowing accurate tracking of heat and mass transfer throughout the process. Control is managed via a 7” touchscreen interface with real-time display and configurable PID controllers for reflux ratio and heating power.

The DIS3000 supports a wide range of chemical engineering experiments including:

-

Hydrodynamic behavior and pressure drop across the column

-

Evaluation of packing efficiency and overflow conditions

-

Analysis of reflux ratio on distillation

-

Mass and thermal balance calculations

-

Column efficiency and product yield calculation

-

Real-time temperature profile monitoring

-

Optional vacuum operation for complex mixtures

Optional features such as bubble-cap trays, condenser flow control, and vacuum traps can be implemented to allow a wider range of experimental capability. Its intuitive interface and flexible setup make it ideal for university seeking to provide hands-on learning in process engineering and separation technologies.