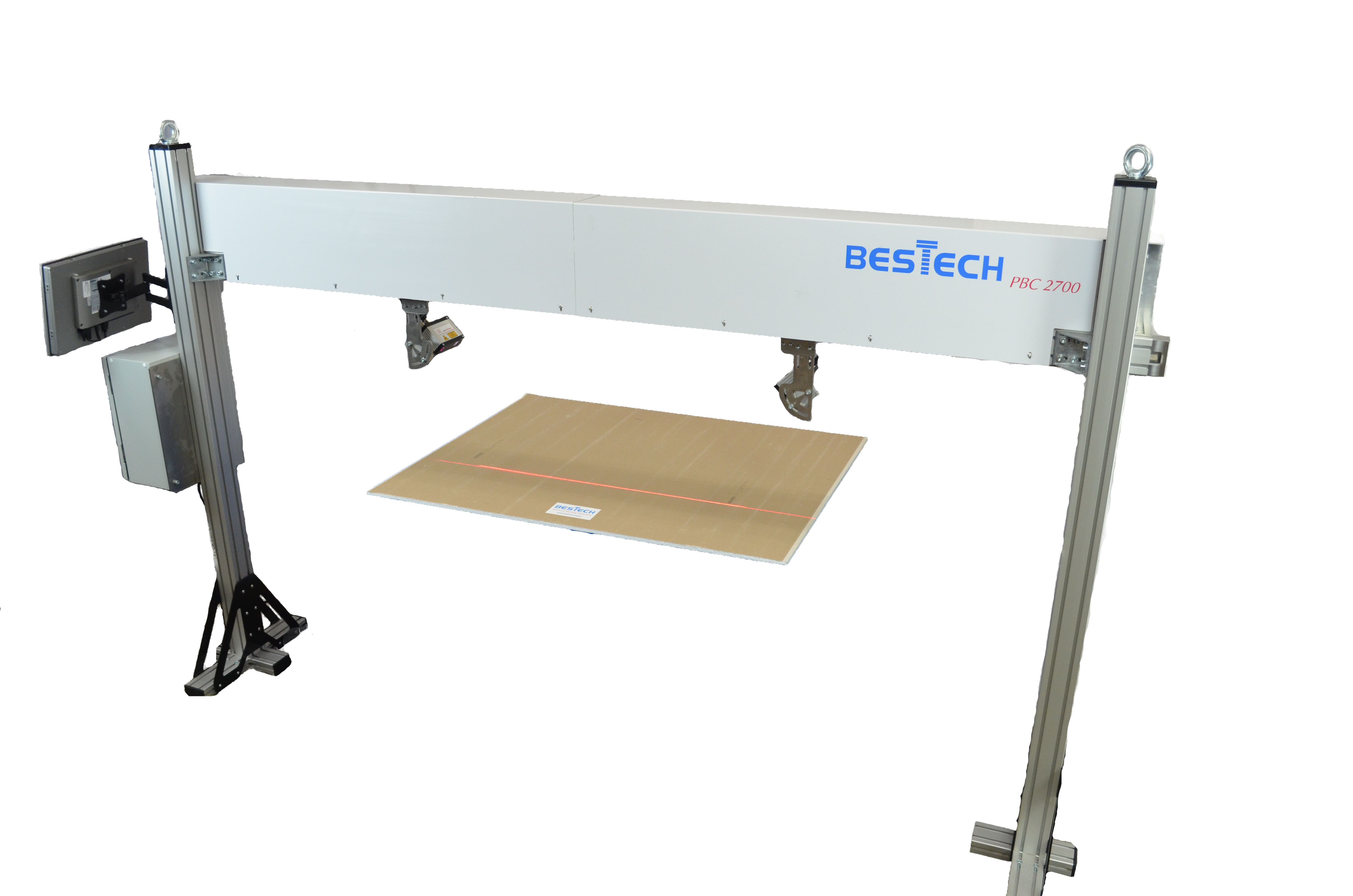

The PBC2700 is a cutting-edge non-contact dimensional measurement system designed for quality monitoring in plasterboard manufacturing. Utilizing advanced laser-line scanning technology, it ensures precise in-line monitoring of plasterboard dimensions and quality during the manufacturing process.

The PBC2700 comes with versatility for positioning at any location along the forming belt to perform real-time measurements of edge angles, board flatness, recess tapes, and detect faults in glue or paper layers. Its innovative design enables manufacturers to maintain consistent quality and identify defects early in the production cycle, minimizing waste and improving efficiency.

This online plasterboard measurement system is equipped with the scanCONTROL smart laser line scanners. With its high-end capability to offer precise measurement at high speed, the PBC2700 delivers unmatched accuracy with 10 measuring points per millimeter and captures up to 25 measurement values per second. The software can be programmed with multiple recipes to supports measurement for various board types, allowing seamless integration into different production setups.

The system comes with user-friendly, touch-screen interface to display measurement profiles in real time, providing operators with instant visual feedback. Faults are easily identified through color-coded alarms that can be configured to different thresholds, enabling quick corrective actions. Additionally, the system offers trend charts for up to an hour’s worth of data, ensuring comprehensive quality control.

Key features include:

- Real-time profiles for immediate monitoring.

- Programmable recipes for different board configurations.

- OPC communication for seamless integration with control systems.

- Flexible programming for enhanced operational efficiency.

The PBC2700 is a reliable, high-performance solution for plasterboard and gypsum board manufacturers aiming to optimize production and ensure product consistency. By leveraging this system, businesses can achieve greater operational control and maintain superior quality standards.