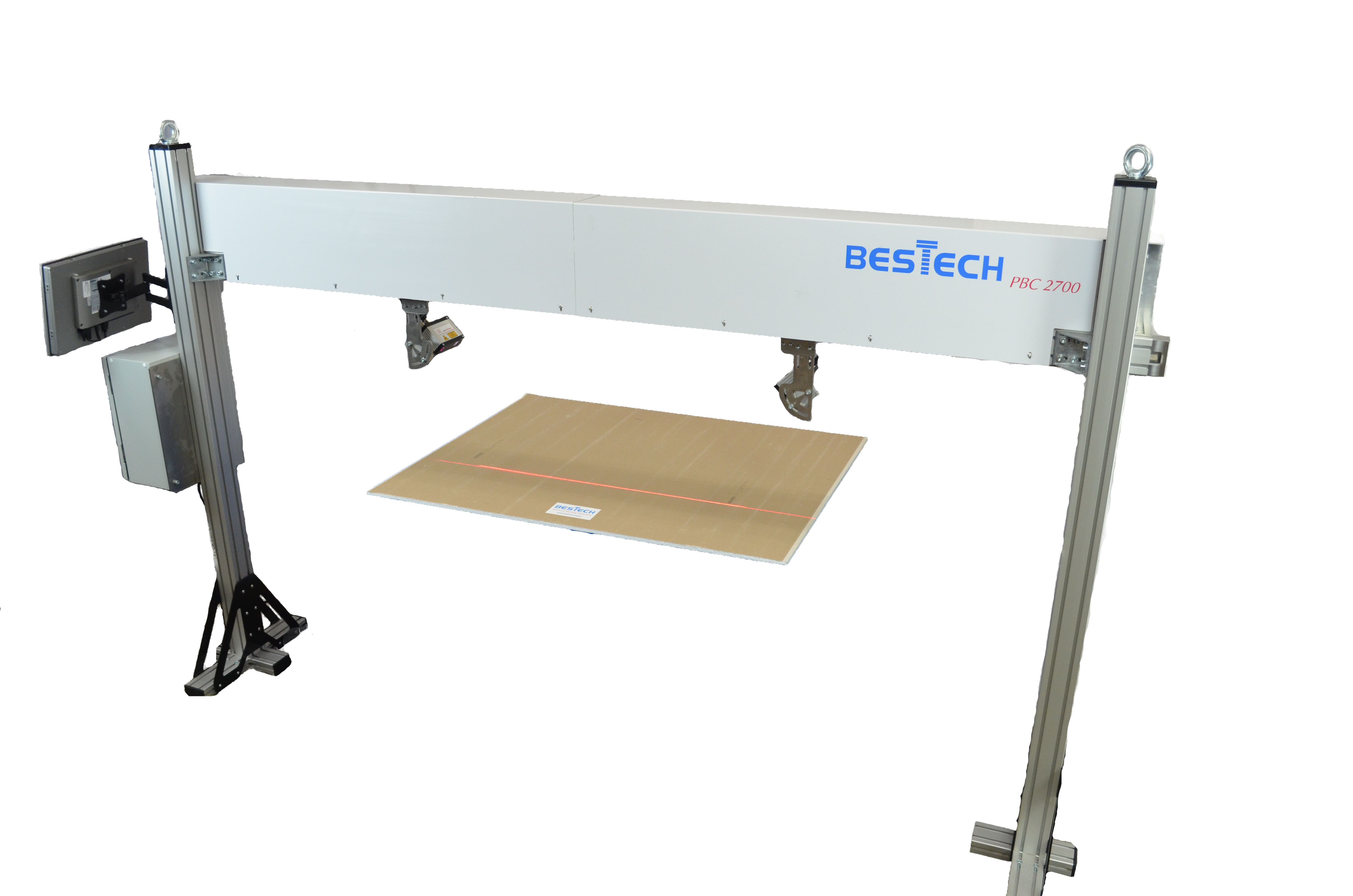

The OCS1600 is a state-of-the-art motorized offline calliper measuring system designed to ensure precise and reliable quality control for plasterboard production. This system offers manufacturers a flexible, accurate, and user-friendly solution for monitoring key dimensions and maintaining consistency across production batches.

Key Features:

- Self-calibrating capability: The system automatically calibrates for every measurement, ensuring consistent accuracy.

- Customizable settings: Easily programmable for multiple board recipes, enabling quick adaptation to various plasterboard configurations.

- Real-time feedback: Displays both top and bottom profiles separately and generates a thickness profile for detailed analysis.

- Segmented board monitoring: The board is divided into 10 sections, each with adjustable upper, lower, and pre-alarm thresholds for fault detection.

- Comprehensive data reporting: Calculates and reports measurements, including board width, recess width, recess depth, and thickness, to an OPC server for seamless integration.

- User-friendly design: Adjustable height for workbenches and an intuitive interface make the system practical and easy to operate.

Key Applications:

- Offline quality control in plasterboard manufacturing.

- Ensuring dimensional accuracy for recesses, thickness, and board width.

- Identifying and rectifying defects to maintain high production standards.