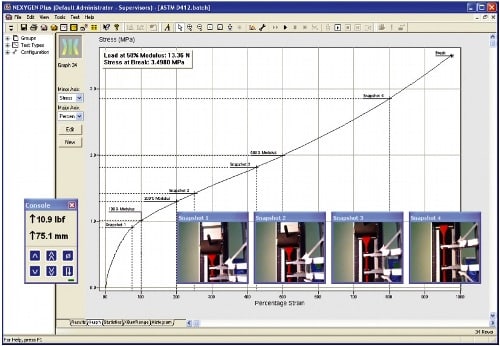

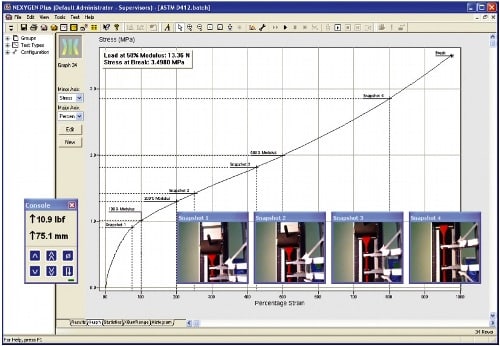

NEXYGENPlus 3 multi-lingual materials testing software is designed for use with Windows©XP or Windows©7. Simple select test from one of its pre-defined test procedures to create any desired tests based on any international standards thanks to the software’s large built-in library of test methods. Video and still image capture help for post-test visual analysis whilst built-in SPC enables continuous monitoring of process parameters such as Cp and Cpk. Collected testing data can be transferred and used externally seamlessly as MS office packages have been integrated into the software. The software is configured to allow rapid and accurate data collection with many built-in functions to ensure free testing. Its powerful analysis and reports tools not only deliver multi-colour graphs with legend in most popular commercial packages like Excel, TXT, ASCII, WORD, and etc. to be printed or emailed, it also provides direct connections to LIMS systems used in laboratories. All testing data are generated and transferred automatically without operator intervention.

You need to have Adobe Flash Player to view demos provided on this page.

| Functions | Features | Download Flash Demo File (audio required) |

|---|---|---|

| Test Creation |

|

how to create a simple test |

| Data Collection |

|

Watch a demo of error free testing & video capture |

| Data Analysis |

|

Demo of automatic MS Excel data exporting View the power & ease of MS Word integration |

| Queries |

|

– |

| Security & Audit Trails |

|

Demo of Security Features |

| Automation |

|

– |

Minimum Computer Specifications for Runing NEXYGENPlus

- USB 2.0

- CD ROM drive, 2.4Hz Processor or better with 3GB RAM

- Microsoft® Word (2000 or later)

- Microsoft® Access® for Security Module maintenance (unless another advanced database is to be used)

- Windows® 7

- Unused COM Port with a 16550 UART (dual column machines only)Simple to set up, operate and maintain

Need assistance with your application? CONTACT US now with your application details.

Enquire Now