The MSFSI02 training stand offers a hands-on learning experience about modern car and demonstrates the workings of a direct petrol(gasoline) injection system. This specialized device includes all the engine management components as in the real car, such as fuel supply, exhaust and ignition systems, helping users understand how these parts interact.

- Includes high and low-pressure fuel supply systems and air-fuel mixture ignition system.

- Includes a complete electric wiring diagram of the direct petrol(gasoline) injection system (FSI) for reading and understanding electrical diagrams, component markings, and use this knowledge for troubleshooting and repairing modern vehicles.

- Analyzes direct petrol(gasoline) injection circuits and the operation of ignition and fuel supply systems.

- Measures fuel injection quantity, injector spray pattern quality, low fuel pressure of the fuel pump, more than 20 electrical parameters via banana plug connectors, electrical signal parameters of each component, high voltage circuit of the ignition system and much more with multiple diagnostic tools.

- Demonstrates synchronization between the crankshaft and camshaft.

- Allows manual adjustment of crankshaft rotation frequency, lambda sensor values, engine and radiator coolant temperatures, NOx sensor values (depend on the system) , exhaust gas temperature (depend on the system), intake manifold pressure, and intake air temperature.

- Displays voltage readings from various electronic system components, including the exhaust gas recirculation potentiometer, accelerator pedal position senders, intake manifold flap potentiometer, fuel pressure sensor, throttle valve potentiometers, intake manifold pressure sensor, engine operation temperature sensor, coolant temperature sensor, and exhaust gas temperature sensor.

- Simulates circuit faults by removing jumpers or adjusting the parameters to incorrect values.

- Uses OBD II 16 – pin standard diagnostic connector to read the information from ECU for reading/erasing fault codes, displaying the operating system parameters (live data), activating the actuators (depends on the control unit), throttle valve adaptation, control unit encoding/configuration and other parameters monitoring.

- Features an electric vacuum pump for intake manifold flaps (ordered separately).

Related products

Autoedu MSLPG01 | LPG training board educational trainer

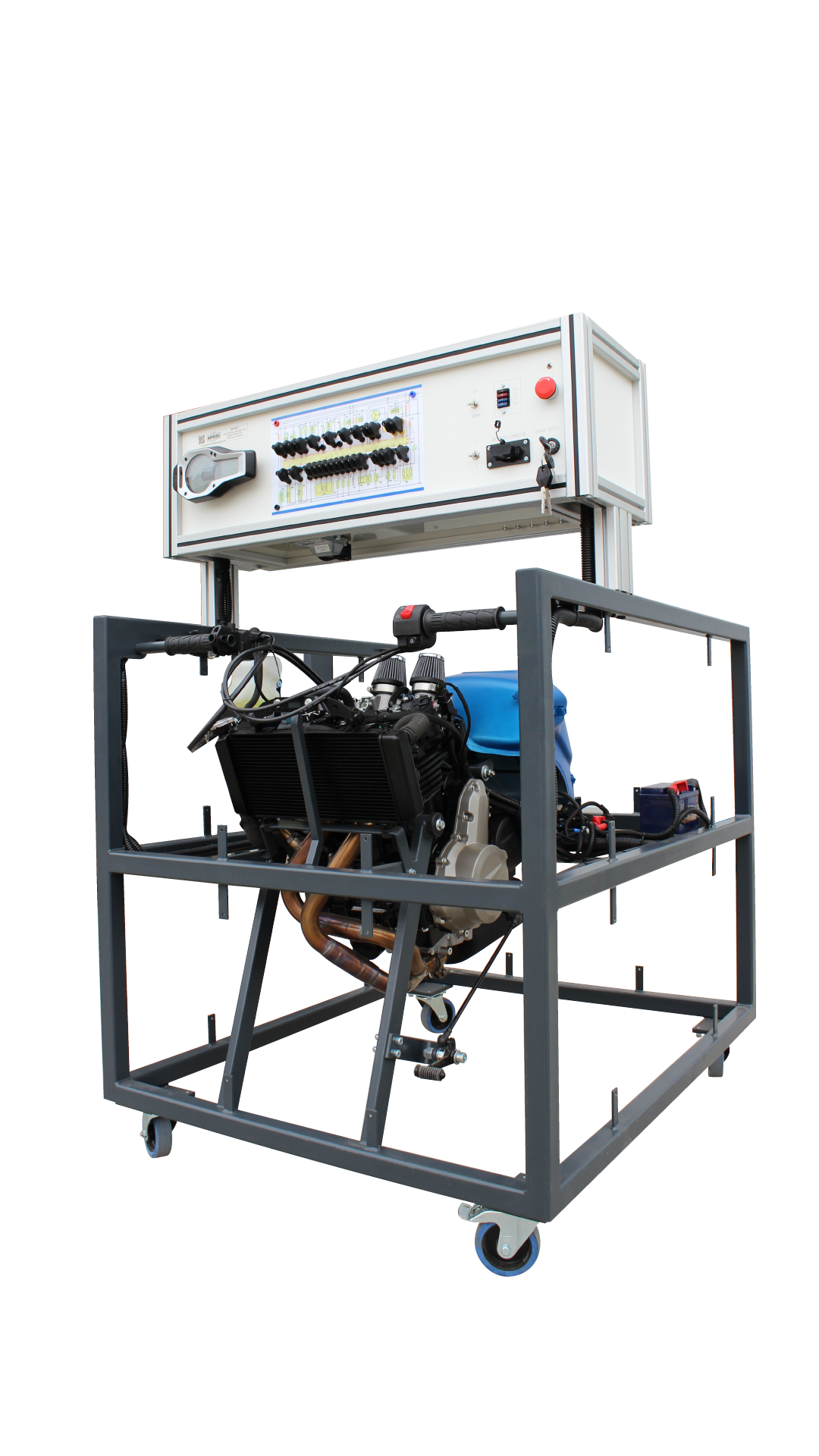

Autoedu MVMC01 | Educational motorcycle engine trainer with a fuel injection system

EM-140S-HY03 - Engine Performance Training System with Consulink Student Learning Platform

Autoedu MVFSI01 | Educational petrol engine trainer with direct injection system FSI