Monitoring the commutator in electric motors

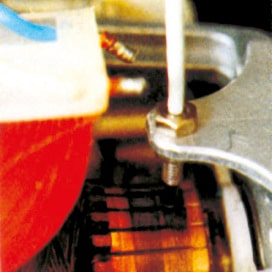

For electric motors located in difficult-to-reach places, continous monitoring of commutator condition is advisable. The commutator monitoring practices are employed in research and development laboratories, for quality control during and following production, or during commissioning of plant. For performing these monitoring tasks, eddy current sensors are incorporated to monitor the mechanical condition of the commutator in DC electric motors or generators.

The eddyNCDT measuring system includes a sensor, an interconnecting cable and a signal conditioning electronics. The eddy current sensors are not subject to wear and cannot influence the commutator. The possible applications of eddy current sensors in the monitoring of electric motor are in the monitoring of shaft vibration and bearing play, detection of the insulating gaps between the individual commutator segments, verification of the free movement of the brushes and the measurement of motor speed.

An eddy current sensor works on the eddy current measuring principle that can be used for measuring ferromagnetic and non-ferromagnetic materials. The sensor is suitable for use in harsh conditions such as oil, dirt, dust, moisture and magnetic interference fields.