Deposition control of coatings

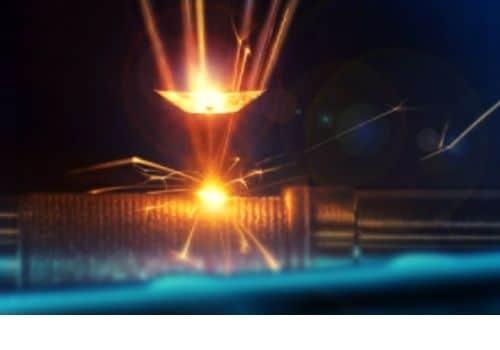

Laser cladding and laser deposition welding are two different methods of coating processes in additive manufacturing. Lasers can be adapted to the welding process in such a way that laser welds (or weld deposits) can be applied, effectively coating a material layer by layer. However, during the coating process, it is essential to monitor the weld deposition for ensuring uniform coating. To cater to this requirement, laser scanners from Micro-Epsilon are used that enable reliable and precise measurements.

These profile scanners detect, measure, and evaluate profiles on different object surfaces without contact. Due to their compact size, it is easy to integrate these scanners in restricted spaces. With high profile resolution, these laser scanners are especially suited for the accurate measurement of objects in the 3D printing industry.